NJEX Odorization Systems for Natural Gas and Propane

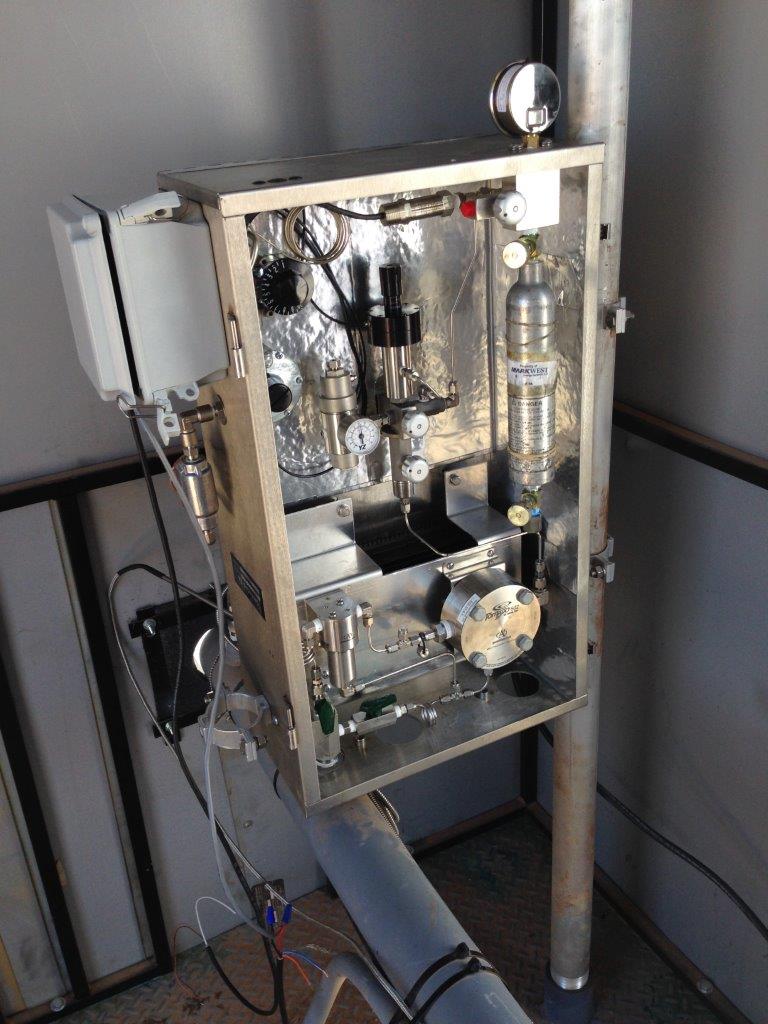

NJEX

NJEX 610

Low-Volume Applications

The NJEX 610 is a low-volume odorization system. The 610 series uses the Z-65 controller to offer a wide range of control and simplicity. In the timer mode, the Z-65 functions as an adjustable recycling timer. In the counter mode, the Z-65 becomes a two digit scaling counter, accepting most types of ow computer pulse inputs in order to achieve proportional to ow injection.

610 Features

- Patented, pneumatically-actuated, positive-displacement, plunger pump

- Intrinsically safe electronics

- 1.44 liters/day (.38 gallons/day) maximum odorant output

- .02 to .1 cc/stroke

- adjustable displacement

- Adjustable stroke rate

- 6 seconds - 99 minutes per stroke

- Easy eld programming

NJEX 6300

Low-Volume Applications

We offer proportional-to-flow odorant injection with our 6300 pump at a displacement from .06 cc/stroke up to .01 cc/stroke. This system is ideal for small city gate stations, municipalities and supplementary odorization facilities where veri cation is critical and the operation does not call for a large capacity system. The 6300 is available in a variety of con gurations and is available as a single unit or coupled with another unit to provide additional system backup (6302 series). Either system can be skid mounted with a choice of standard ASME tank arrangements or numerous other choices to meet your needs.

6300 Pump Features

- Patented, pneumatically-actuated, positive-displacement, plunger pump

- Intrinsically safe electronics

- 6.7 liters/day (1.76 gallons/day) maximum odorant output

- .06 to 0.1 cc/stroke adjustable displacement

NJEX 7300

The Industry Flagship

The NJEX 7300 series was our first system and remains the industry standard for most user applications. This mid-use, primary odorizer is capable of accurately injecting up to 67 liters/day (17.6 gallons/day). The NJEX 7300 can odorize up to 320 MMSCF/Day, based on an injection rate of .75 lbs/MMSCF. The system is flexible and is available in a single unit, the 7300 series or for increased capacity and 100% backup capability we offer a dual unit, 7302 series. Both units can be upgraded to include skid packages and other options for enhanced operational capability.

7300 Pump Features

- Patented, pneumatically-actuated, positive-displacement, reciprocating plunger pump

- Teflon© diaphragm isolates all dynamic seals from the odorant

- Intrinsically safe electronics

- 67 liters/day (17.6 gallons/day) maximum odorant output

- .2 to 1.0 cc/stroke adjustable displacement

NJEX 8300

High-Volume Injection

The NJEX 8300 series is designed for high-volume applications and delivers a maximum of 257 liters/day (68 gallons/day). The NJEX 8300 system can odorize up to 1.25 BSCF/ day based on an injection rate of 75 lbs/MMSCF.

Ideal for large transmission companies or large city gate stations, these big-injection odorizers have standard built-in features for enhanced quality and a variety of options to meet your process needs.

The system is available in a single unit (8300 series) or dual unit (8302 series) and can be upgraded to include a skid-mounted package with onboard odorant storage tank, containment skid and a wide variety of other options.

8300 Pump Features

- Patented, pneumatically-actuated, positive-displacement plunger pump

- Te on® diaphragm islolates all dynamic seals from the odorant

- Intrinsically safe electronics

- 257 liters/day (68 gallons/day) maximum odorant output

- 6cc/stroke injection

- Maximum of 30 strokes/minute